Description

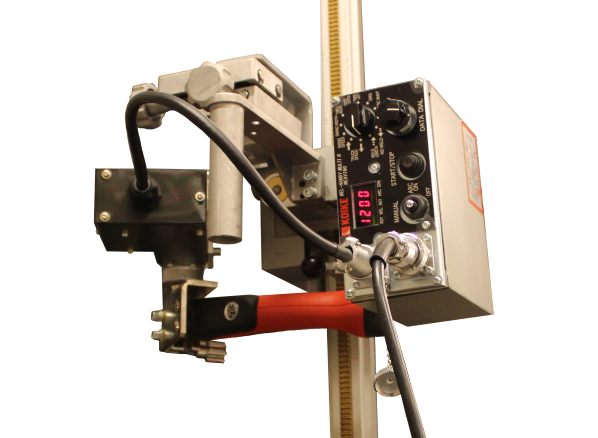

The IK-72W series is used for straight welding in horizontal and vertical positions using 1 dimensional rail and curved and twisted plane welding using 2 and 3 dimensional rails. By using same rail system as the cutting machine IK-72T, cutting and welding can be done with IK-72 system in convenient and lightweight package.

Features

- Light weight at 5.5 kg (W) / 7.6 kg (WEAVING)

- Two models:

- IK-72W: Tack welding

- IK-72W WEAVING: Tack and weaving welding - Carriage positioning by limit switch

- Advanced tack welding functions

- Digitally controlled weaving and tack welding (Weaving model)

- Shares same rail system as the cutting machine IK- 72T; making it possible to weld after cut.

Scope of delivery

Technical specifications

| IK-72W | |

|---|---|

| Machine weight | 5.5 kg |

| Travel speed | 20 - 600 mm/min. |

| Guiding method | IK-72 rail system |

| Driving method | Rack and pinion |

| Torch adjustment: Up/down | 45 mm |

| Torch adjustment: Forward/Backward | 45 mm |

| Torch holder diameter | 16-20 mm |

| Automatic stop function | Limit switch on each end of carriage |

| Weaving unit WU-5R | - |

| Welding method | Continuous, Tack/Stitch welding. Weaving/oscillation optional. |

| Power & signal cable | Power and signal integrated Y-branch cable |

| Torch holder diameter | 16~-20 mm |

| Position adjustment by limit switch | Yes |

| Encoder motor for precise speed control | Yes |

| Digital display | Yes |

| Crater fill function | Yes |

| Input power | DC24V |

| IK-72W Weaving | |

|---|---|

| Machine weight | 7.6 kg |

| Travel speed | 20 - 600 mm/min. |

| Guiding method | IK-72 rail system |

| Driving method | Rack and pinion |

| Torch adjustment: Up/down | 45 mm |

| Torch adjustment: Forward/Backward | 45 mm |

| Torch holder diameter | 16-20 mm |

| Automatic stop function | Limit switch on each end of carriage |

| Weaving unit WU-5R | Included |

| Welding method | Continuous, Tack/Stitch welding. Weaving/oscillation standard. |

| Power & signal cable | Power and signal integrated Y-branch cable |

| Torch holder diameter | 16~-20 mm |

| Position adjustment by limit switch | Yes |

| Encoder motor for precise speed control | Yes |

| Digital display | Yes |

| Crater fill function | Yes |

| Input power | DC24V |