Description

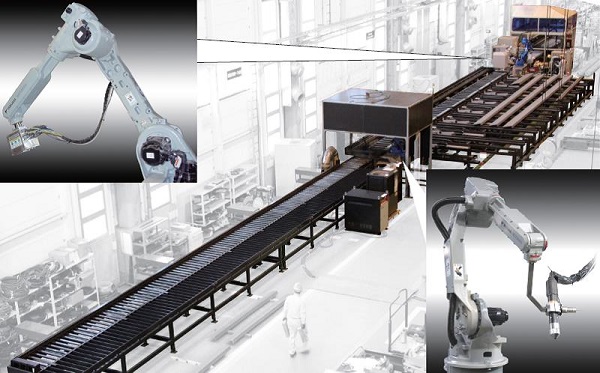

KOIKE Profile Processing System is a processing line exclusively for profile steel, cutting and marking, mainly used in the manufacturing site of shipyards.

The cutting and Marking, can be performed completely automatic, from the load of material to the dispatch, by the combination of conveyer, picking device, profile steel carriage, and robots. The system contributes significantly to the improvement of productivity. We can provide the most suitable production line, which meets the requirements of the customer.

Features

- High quality cutting is achieved with the KOIKE SUPER 400A oxygen plasma

- Teaching is not necessary. Robot data creation is possible with the shape data of the CNC Cutting

- Fume extraction is improved by fixing the position of the Cutting robot.

- Free edge rounding (2R3P) cutting is possible, reducing the grinder process.

- The marking quality is stabilized by using ink jet dot marker.