Description

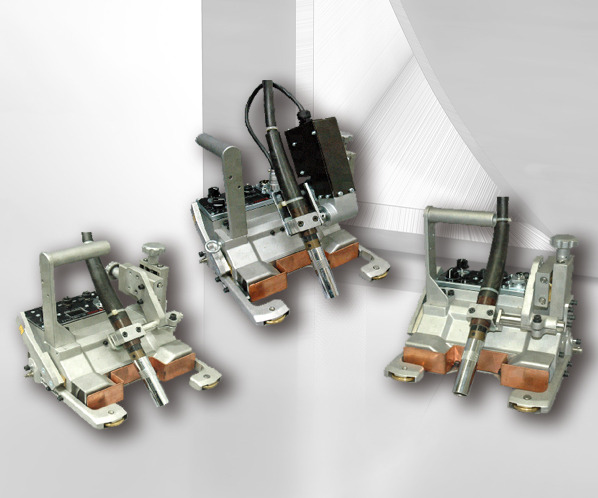

WEL-HANDY MULTI II Standard

WEL-HANDY MULTI II series succeeds merits of conventional model such as light weight, strong traction force, and

extensibility for various works. And WEL-HANDY MULTI II series are renewed for higher performance.

7 kg body weight of high portability, magnet adsorption, and 4 wheels drive provide running stability (constant speed).

Features

- Built-in Permanent

Magnet

By turning down the lever on side of machine, built-in magnet is attracted to the steel plate, it demonstrates the high traction pulling the torch lead.

- Aluminum Die-cast

Body

The aluminum die-cast molded body provide its light-weight and sturdy.(Net Weight 7kg by Standard Specification)

- Torch Slide

unit

Each 45mm of adjustment has been ensured in back and forth, up and down.Smooth operability, it can be fine adjusted the torch position even during welding.

- Guide Roller

Arm

No need to install a rail.Guide Roller Arm will trace the surface of vertical plate.Besides standard type shown in the picture,other types of Guide Roller Arm are also available as option for various different applications.

Scope of delivery

Technical specifications

| Model Name | WEL-HANDY MULTI II

(Standard) |

|||

| Machine Weight | Standard Magnet

Model: 6.9 kg Strong Magnet Model: 7.5 kg |

|||

| Machine Dimension(W×D×H) |

277mm(W)×255mm(D)×264(H)

|

|||

| Traction Force | 16kg | |||

| Gap(F.L. ~ Bace Board) | 6mm | |||

| Magnet

Up and Down Mechanism |

Magnet Lever | |||

| Driving Method | 4-Wheel Driving Rubber Roller (Chain Transmission) | |||

| Magnet-type | Permanent Magnet | |||

| Traverse Speed | 50~1500mm/min | |||

| Tracing Method | Guide Roller (being pushed against Vertical plates) | |||

| Applied Posture | Standard Magnet Model: Horizontal position Fillet

Welding Strong Magnet Model: Vertical position Fillet Welding |

|||

|

Torch |

Torch Angle | 40°~55° | ||

| Up and down | 45mm | |||

| Forward

and Backward |

45mm | |||

| Forward

and Angle |

5° Angle at both Forward / Backward | |||

|

Automatic Stop Function |

Limit

Switch (equipped at both sides of Carriage at FL +20 mm height) |

|||

| Fine

Adjustment of Carriage Position |

Included | |||

| Non-Welded Portion | Approximately 270

mm (in total at both Start and End point) |

|||

| Power Cable | Y-Branch Cable (Power and Signal cable

Integrated) ● Carriage ~ Branch: 6 m, ● Branch ~ Power: 10 m, ● Branch ~ Wire Feeder: 0.5 m (with matching Panasonic-type Connector) ※ Please consult when using welding machine other than Panasonic. |

|||

|

Welding Torch |

Straight WHM (C) - 350S & 500S | |||

| Curved 350A & 500A | ||||

|

Torch Hold Diameter |

Straight Torch Holder: φ20 mm | |||

| Curved Torch Holder: φ16~20 mm Diameter | ||||

| Moter | DC Motor with Encoder | |||

| Input Power | AC100~240V 50/60Hz | |||